Why Are Anti-Fretting Coatings Used in Gas Turbine Engines?

It’s a simple law of physics that when two surfaces come into contact there will be some friction and some resultant wear. In gas turbines surfaces come into contact via cyclic vibrations of motions that can leave particles behind that can adhere and cause further wearing. This is why protective measures such as an anti-fretting coating can be used to protect cylinders and make them last longer.

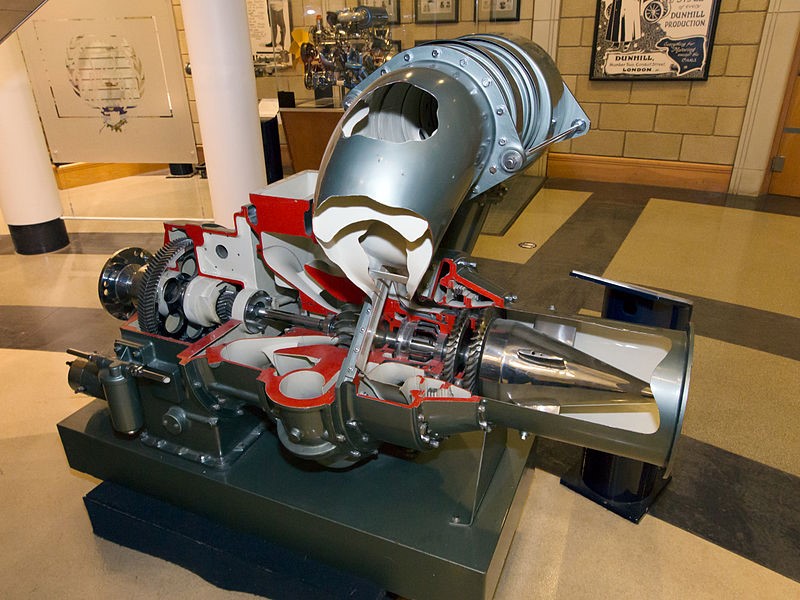

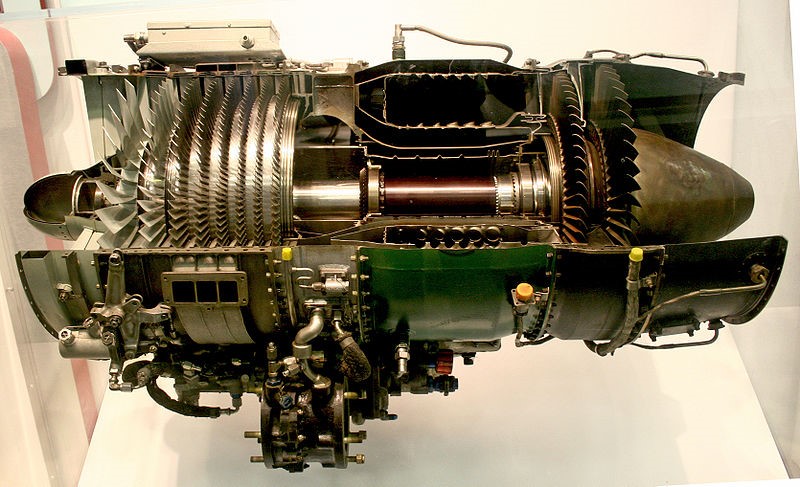

Image Credit

What They Do

These coatings are essentially employed to protect surfaces for great durability. The main areas that really benefit from this procedure are the dovetail slots found in compressor discs. When they are being used the lateral movement of blades, combined with centrifugal loading, can lead to conditions that cause fretting, which could be either wear, corrosion or a combination of both. Centrifugal forces can be quite powerful. For more on this phenomenon, see this report in The Guardian.

Extending Durability

The right coatings and lubricants can protect against micro cracks and a range of other wear issues. Different solutions exist, which include dry film lubricants and fluid lubricants. The nature of the turbine needs to be taken into account when selecting the right coating, as they have different characteristics, including the speed at which they rotate, the pressures they are operating under and what band of temperatures the turbines are being used in. A dry film lubricant is a substance that is solid and allows surfaces to interact with minimal resistance or friction.

Typical compounds used as dry lubricants in a variety of engineering situations include tungsten disulphide, graphite and molybdenum disulphide. If you want to find out more about anti-fretting solutions or about UK surface engineering, then a sensible first step would be to contact a reputable site such as https://www.poeton.co.uk, where the staff can give you guidance and advice regarding options in UK surface engineering.

Damage as a result of fretting is a significant concern for gas turbine engine varieties. Corrosion and wear can cause damage to the surface of components, which can lead to cracking and breakdowns. Using the right coatings to protect against fretting is a worthwhile form of insurance to guard against expensive repairs. Using the right coatings should also increase the durability and reliability of the engines and assist them to deliver higher and more consistent performance.

Leave a reply