Turning a 3D printer into a moulding machine

It wasn’t very long ago that the 3D printer seemed like an idea straight out of science fiction; today, the 3D printer is very real and is definitely here to stay.

Image Credit

Despite all the hype that surrounds the technology, some pundits believe it has the capacity and scope to become even bigger than the internet.

3D printing is endlessly versatile

It is a bold claim, but one that simply can’t be proved – or indeed, disproved – at present. Only time will tell. What we know for certain is that the 3D printer certainly has the ability to become useful, if not essential, across a variety of different fields.

A brief online search will find guides for using a 3D printer for all sorts of projects, from mobile phone holders to intricately-shaped pen holders; therefore, it is perhaps not surprising that some individuals have seized upon the technology’s innate usefulness across a number of industrial projects.

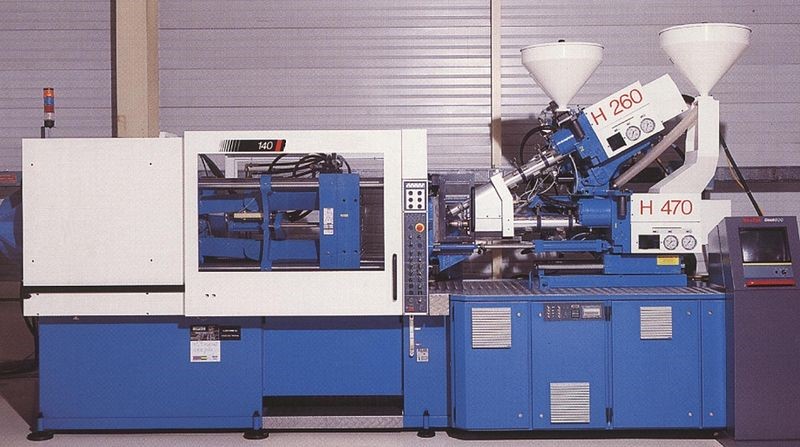

Take silicone moulding as an example. Companies such as https://www.meadex.co.uk specialise in the manufacture of all types of silicone, plastic and rubber mouldings, which can be used for all sorts of industrial purposes. The injection moulding process requires plastic to be squirted into a pre-designed mould, so it is hardly surprising that some clever boffins have seized upon the idea of using 3D printers to inject mouldings.

Finely-detailed moulding process

The very small and detailed parts that are needed for all sorts of purposes and across a diverse range of industries can be easily created with injection moulding machines; however, it is surprising how the extruder connected to a 3D printing machine can perform a nearly identical task when correctly set up for the purpose.

A 3D printer heats plastic to a very high temperature. Once it has melted, the plastic is forced through a small orifice in the extruder. All that is needed is a silicone mould. Anyone with a 3D printer and a smattering of knowledge can create small, plastic parts from the comfort of their own home or workspace.

A little silicone RTV rubber for the mould and a few children’s blocks for the sprues and you are good to go. All that is needed now is to fill the model from your printer and the job is done!

Leave a reply